Wolfurt, Austria – The Doppelmayr Group, headquartered in Wolfurt, Austria, is a global leader in the development of ropeway systems for passenger and material transport as well as advanced intralogistics solutions. With more than 3,500 employees, the company designs, manufactures and services ropeway installations in over 50 countries worldwide.

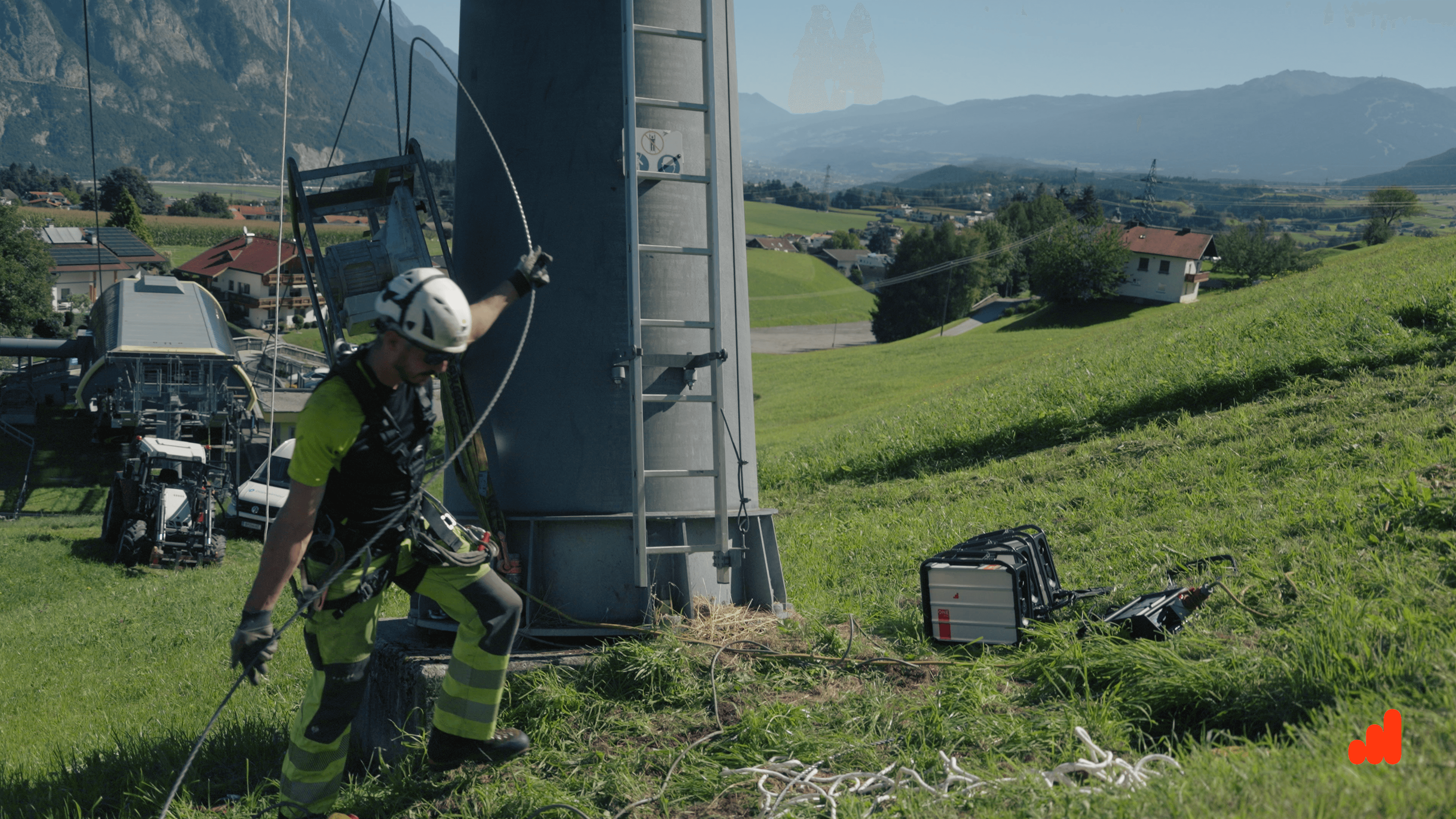

For Doppelmayr, regular maintenance of its customers’ ropeway systems is a critical factor in ensuring customer satisfaction, as it directly impacts both safety and system availability. One particularly important task is the inspection and overhaul of the sheave battery assemblies mounted on the ropeway towers. This service must be carried out at prescribed intervals on every ropeway installation.

Rollenbatterie-Revision an Seilbahnstützen mit Instagrid LINK MAX

The challenge: maintenance in remote locations without power supply

Service technicians frequently work in remote regions, at high altitudes and in difficult terrain. At many tower locations, no electrical infrastructure is available. Until now, this meant that petrol-powered generators had to be transported to the site in addition to tools and materials—often a significant logistical effort before any actual work could begin.

Simplifying the work: Instagrid ONE and LINK MAX

With the portable battery solution Instagrid ONE, generators can be replaced and overall effort significantly reduced. The unit weighs just 20 kg, is robust and weather-resistant, and delivers 3.6 kW of continuous power with peak outputs of up to 18 kW—quietly, emission-free and with grid-quality electricity.

For operating the winches required during sheave battery maintenance, Instagrid LINK MAX is used in addition. This extension connects three Instagrid ONE units to form a mobile 400-volt three-phase power supply with peak outputs of up to 54 kW, enabling demanding equipment to be operated reliably without a fixed grid connection.

The result: efficiency, safety and sustainability

By using Instagrid, the transport of heavy generators and fuel is eliminated and work processes are significantly simplified. There are no exhaust fumes, no noise emissions, and communication between team members is improved—an important advantage, especially in exposed or confined working environments.

Conclusion

By using Instagrid for sheave battery maintenance, Doppelmayr relies on a sustainable solution that increases comfort and efficiency in day-to-day service operations. It addresses key challenges in ropeway maintenance: lack of power infrastructure, complex logistics, noise and emissions—demonstrating how battery-based mobile power can support safer and more efficient work in demanding environments.

Get to know more about Instagrid LINK MAX or request a demo?