Getting the job done on a busy construction site, and getting the job done well, means enabling both your crew and equipment to work as smoothly as possible. Achim Eldracher from Artur Weiler, a subsidiary of construction giant Harsch, found that Instagrid’s clean mobile power supplies improved on-site efficiency and significantly reduced set up time.

We no longer have lengthy waiting times, time spent looking for equipment. We arrive in our service vehicles, the people get out, Instagrid units out, connect the devices, and off we go.

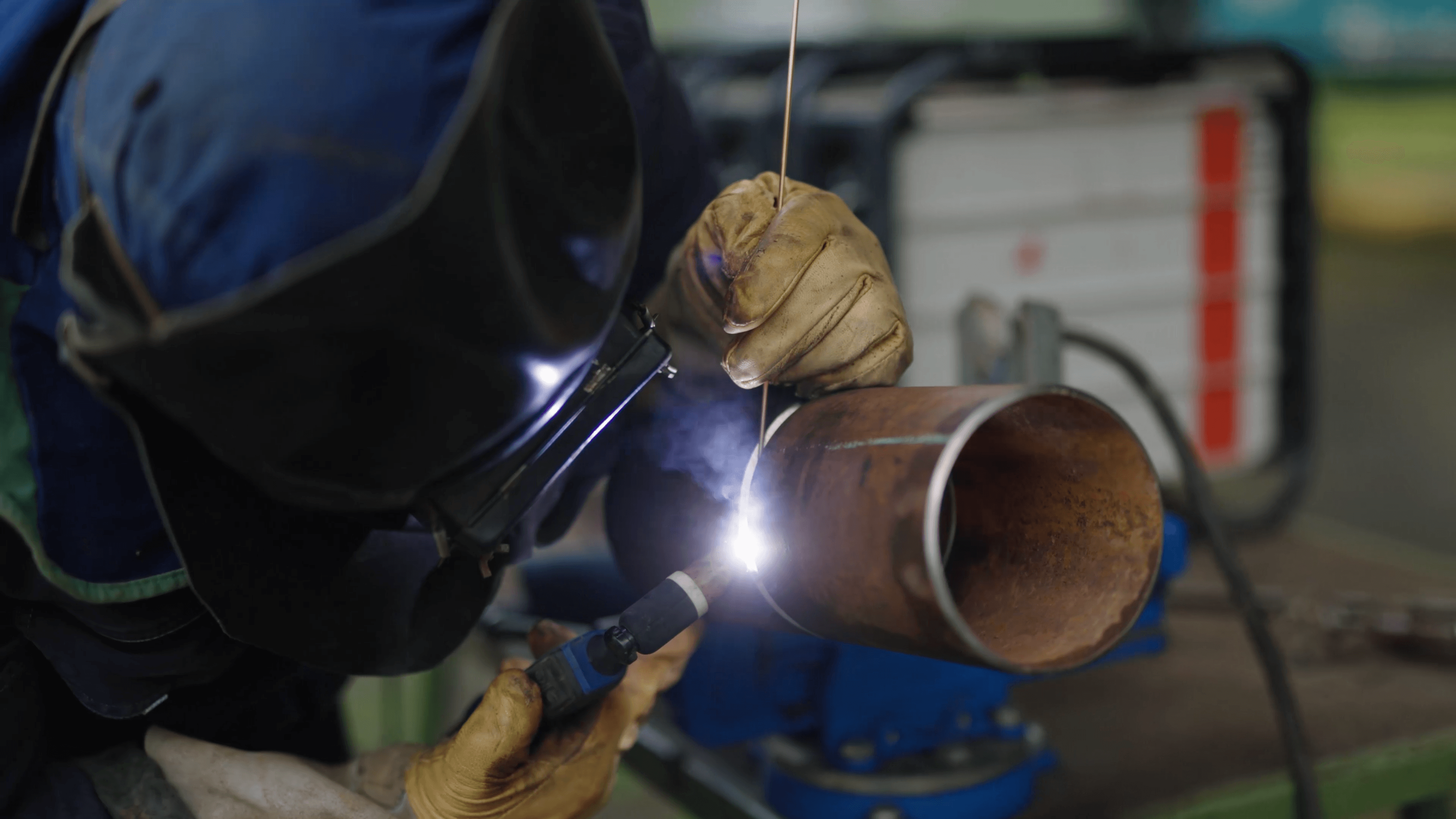

Welder Jan Bachmann also had a positive experience when using three Instagrid ONE units connected with our new smart power distributor, Instagrid LINK. He highlights the consistency and reliability of the power supply during welding projects as a huge plus for his work.

With three Instagrid units, you get through the day perfectly. And there is definitely still a buffer for the next day. If one battery runs out and you have three Instagrid units connected, you don’t notice any drop in power during the welding process. The other power bank kicks in immediately, ensuring no loss in quality because the welding current provided by the Instagrid units is maintained constantly.

Between Instagrid and traditional combustion generators, there was no contest. Furthermore, the Artur Weiler team found Instagrid’s portable power supply to be a highly cost-effective solution that also helped them cut down significantly on on-site CO2 emissions.

Discover the virtually limitless possibilities offered by Instagrid here.

Read more on how the new Instagrid LINK is revolutionising the construction industry in this testimonial from the city of Ludwigsburg’s technical services team.